Hours after facilitating a panel discussion surrounding industry sustainability in partnership with Green Light Alliance, Stickbulb cofounders Russell Greenberg and Christopher Beardsley sat down with LUMA to discuss getting to know their audience, product innovation, and challenging the supply chain.

The current greenwashing climate of exaggerated claims and laughable timelines surrounding the climate crisis has cultivated a level of justifiable skepticism among designers and lighting specifiers. Stickbulb’s informed moves show their rejection of being lumped into the ‘false claims’ category of lighting manufacturers.

Helping to brand the legacy of their current showroom, the company turned New York's oldest steel mill and former textile factory into their new home base, leaving forgotten sewing tools and seamstress buttons strewn across the floors as a nod to trades past. It’s easy to see that Stickbulb’s origin story has reuse baked into its DNA. “We started by using thin profiles of unusable wood, marrying that with new (at the time) thin form factor LED. It challenged us to find a use for the otherwise futile material,” said cofounder Greenberg. Erected in a prototyping woodshop in Long Island City in 2012, Stickbulb capitalized on New York’s large wood waste.

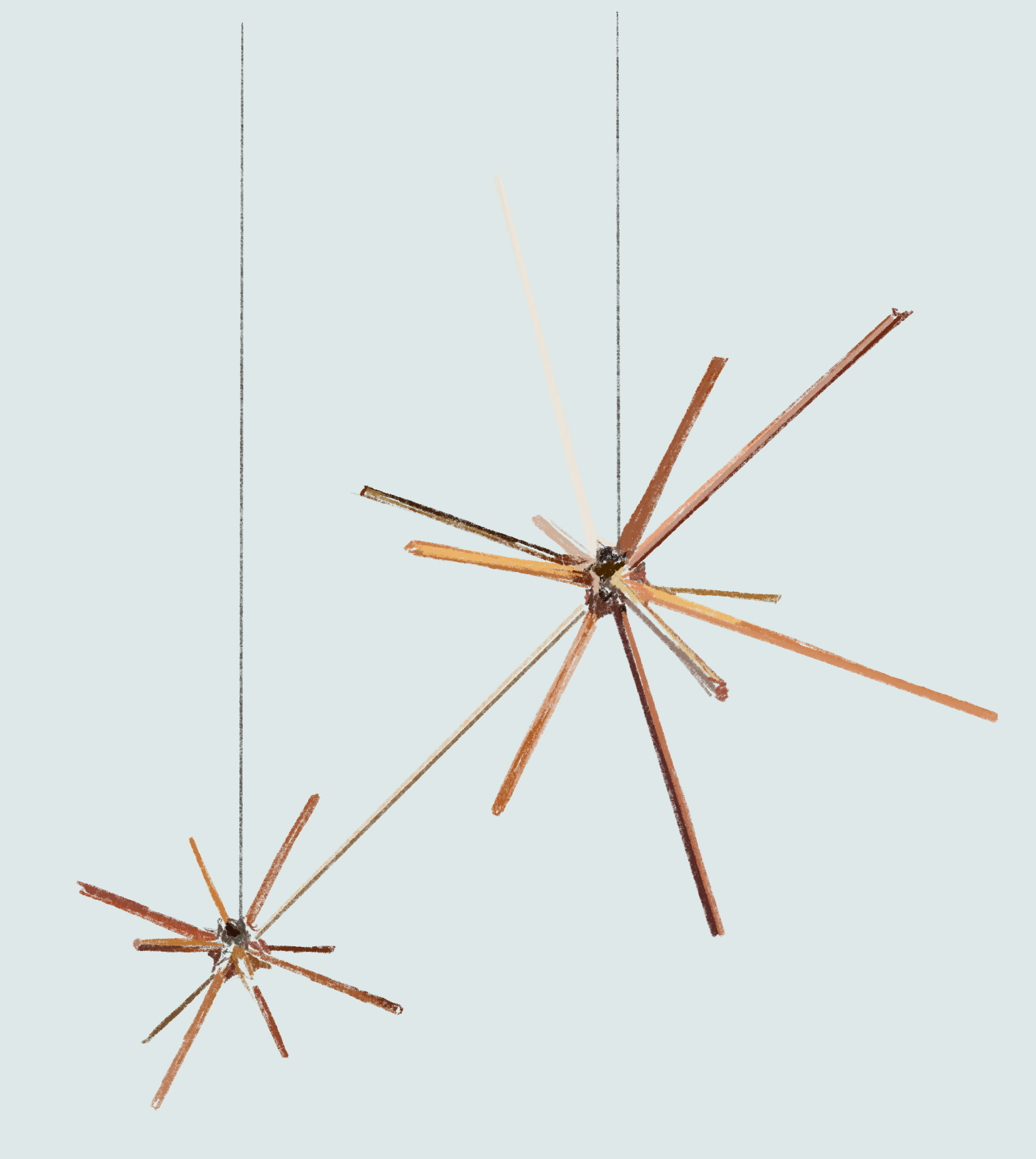

“We’re obsessed with the character and emotion of wood. We’re dispelling the myth that new is better,” says Beardsley. One of the more unique woods utilized in Stickbulb’s modular lighting design is born from the destruction of forgotten architecture. The redwood from New York’s former water towers is carbon-dated back 300 years. “It’s been locked up in the urban jungle, just waiting. There is no old and there is no new, there’s just being resourceful,” says Greenberg. “We have also started to utilize the Life Cycle Assessment (LCA) process in the core of our design and decision making.”

While material contentiousness is essential, it’s becoming mandatory among consumers and the demand for additional manufacturer transparency is key to a thriving industry. “Walls have been built that don’t need to be there. Specifiers and distributors are on two different telephones when we should all be on the same line,” says Beardsley.

Stickbulb became Climate Neutral Certified in 2020 and uses the Climate Neutral Certification process to help quantify their carbon footprint and use the data to empower themselves to make earth-first design and manufacturing decisions.

“We don't just want to offer a product range that's ‘close’ to what you want, we need to know our audience.” The sentiment expressed by Greenberg shows Stickbulb’s desire to push product innovation in a structured way that’s mutually beneficial to all parties. “In a dream world, we’re making each other money and sharing critical pieces of information to change customer demand for the betterment of our planet.”

As Stickbulb works to avoid blind spots, they’re eagerly opening communication channels to better understand the mental state of specifiers. “We’re seeking good and bad feedback from those who are naturally interested in solving problems with us. Fielding notes from specifiers is an essential piece to the puzzle,” says Greenberg.

Whether the common denominator is product innovation, lessening negative environmental impact, or all of the above, it can’t be done without stepping out of previously designated lighting silos. Moving the industry forward alongside manufacturers that hold space for unglamorous feedback while pushing to achieve goals that align with LUMA’s greater objective is a celebrated connection.

Illustrations by Isa Lichtenberg (LUMA)

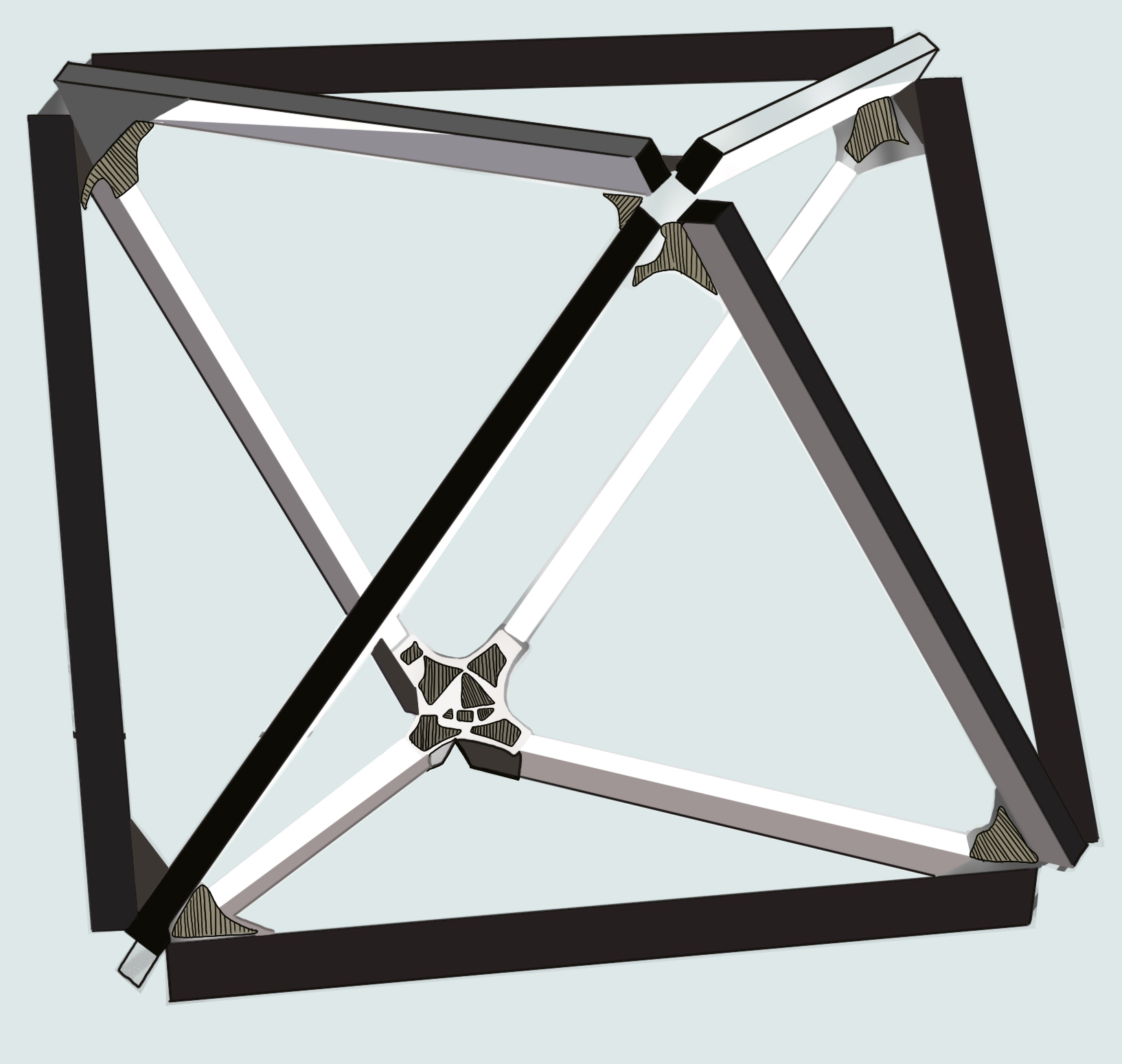

Product Imagery Provided by Stickbulb

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8